The unit uses a modularized sectional combination method based on the specific planned use and function. The optional functional sections of the air handing unit include: new air inlet section, air return section, filtration section, mixture section, refrigerating section, heating section, humidifying section, fan section and silencing section.

The unit uses a modularized sectional combination method based on the specific planned use and function. The optional functional sections of the air handing unit include: new air inlet section, air return section, filtration section, mixture section, refrigerating section, heating section, humidifying section, fan section and silencing section. Thomas & Betts [REZNOR ] fuel gas combustion and control technology is used to make the unit more reliable and efficient and better adapted to the requirements of the Chinese users.

The fuel gas air handling unit is safe, economical, energy-efficient, environmentally friendly and easy to operate. We try our best to provide our clients with safe, reliable, easy to use and elegant ventilation products as well as advocate user-friendly air handling concepts.

- The combustion efficiency is near 100%, which makes the unit economical to operate and environmentally friendly with lower emissions than traditional units;

- 100% fresh air compensation heating; air can be supplied by mixing the return air and new air with the proportion of new air to return air as high as 2:8;

- The Design 74 stainless steel burner is used to carry out infinite adjustment of the heating control unit to control combustion and the turndown ratio can be as high as 30:1;

- The design and manufacturing of the direct combustion burner complies with Z83.18 certification requirements of the ANSI (American National Standards Institute) and FM/IRI industrial insurance requirements;

- The design and processing of unit case comply with the requirements of national combined air-conditioning units;

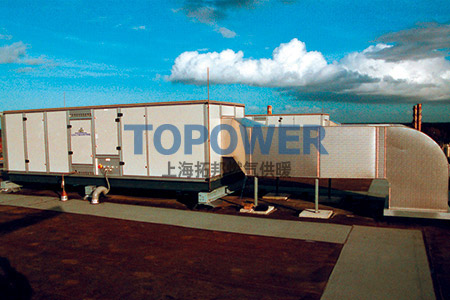

- It can be installed indoors or outdoors;

-

A cooling coil or evaporative cooling unit can be used.

Output heat: 74-5,850KW

Air volume: 1,200-240,000m3/hr

We can design and select patterns based on the client’s requirements. For more details, please consult our technical department.

GAZ INDUSTRIE’s fuel gas air handing unit generally needs massive outdoor fresh air to compensate for the buildings or environmental exhaust air, such as in a plant, warehouse, painting room and supermarket.