BT series fuel gas IR radiant tube heaters are the latest product researched and developed by GAZ INDUSTRIE in 2003 and launched in the European, Chinese, U.S. and Japanese markets simultaneously on November 1, 2004. The main case of BT series is in the advanced integral structural design which represents patented technology of GAZ INDUSTRIE. The burner and induced draft fan are set inside an integrated case with an elegant appearance, reasonable structure. In addition, the installation, debugging and after-sales maintenance is easy and convenient. BT series products have been widely used in China and became quite popular among many users such as CNHTC, Volvo Trucks (China) Co., Ltd., the Import & Export Product Exhibition Center of Tianjin Free Trade Zone and Tianjin Tropical Plant Sightseeing Garden.

BT series fuel gas IR radiant tube heaters are the latest product researched and developed by GAZ INDUSTRIE in 2003 and launched in the European, Chinese, U.S. and Japanese markets simultaneously on November 1, 2004. The main case of BT series is in the advanced integral structural design which represents patented technology of GAZ INDUSTRIE. The burner and induced draft fan are set inside an integrated case with an elegant appearance, reasonable structure. In addition, the installation, debugging and after-sales maintenance is easy and convenient. BT series products have been widely used in China and became quite popular among many users such as CNHTC, Volvo Trucks (China) Co., Ltd., the Import & Export Product Exhibition Center of Tianjin Free Trade Zone and Tianjin Tropical Plant Sightseeing Garden.

Product characteristics: full patented product of GAZ INDUSTRIE

- The main case has an integrated structural design with excellent heat compensation, stable operation, low noise and long service life;

-

Safe and reliable, it is equipped with five major safety protection systems

◇Double electromagnetic air inlet control system

◇Microcomputer program controlled ignition system

◇Ion flame monitoring and combustion control system

◇Flame-out protection system

◇Independently-controlled over-voltage/under-voltage protection system - A negative pressure combustion system, column flame Venturi burner and central flame control system are used. The even columnar type flame can be as long as 5m. The outer flame always remains a certain distance from the inner wall of radiant tube. Combustion is very complete. CO contents of tail gas are 0-4ppm with the thermal efficiency above 90%. It has outstanding advantages related to environmental protection and energy efficiency;

- U-shaped radiant tube design and patented reflector allows good radiation effect and even distribution of infrared radiation, bring a soft and comfortable experience to the human body;

- The independent heating system can be formed by one or several sets of equipment to satisfy both local and central heating requirements and the heating requirements of special production processes;

- Both installation and overhauling are flexible and convenient. Neither internal exhaust nor external exhaust tail gas will cause adverse effects on the buildings and the arrangement of processing equipment. The overhauling or movement of individual pieces of equipment will not affect the operation of the entire heating system.

Energy applied: natural gas and liquefied petroleum gas (LPG)

| Model | BT23EU | BT34EU | BT51EU | ||||

|---|---|---|---|---|---|---|---|

| Heat input | 23 kw | 33 kw | 50 kw | ||||

| Gas connection pipe | DN 15 | ||||||

| Electrical connection | 220V 50Hz | ||||||

| Fuse protection burner | 5A | ||||||

| Starting electrical power | 115VA | ||||||

| Funcionning electrical power | 80VA | ||||||

| Gas type | G20、G30 | ||||||

|

Gas heating value |

G20 | G30 | G20 | G30 | G20 | G30 | |

|

36 MJ/m3

|

46 MJ/kg

|

36 MJ/m3

|

46 MJ/kg

|

36 MJ/m3

|

46 MJ/kg

|

||

| 8600 kcal/m3 | 11000kcal/kg | 8600 kcal/m3 | 11000kcal/kg | 8600 kcal/m3 | 11000kcal/kg | ||

| Intake pressure | G20:2000 Pa G30:5000 Pa | ||||||

| Concumption | 2.14Nm3/h | 1.64kg/h | 3.21Nm3/h | 2.34kg/h | 4.76Nm3/h | 3.55kg/h | |

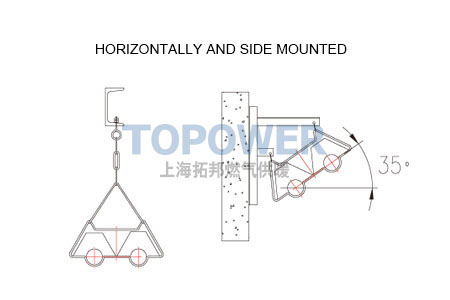

| Minimum mounting height(m) | Horizontal hanging | 3.6 | 4.5 | 5.5 | |||

| Wall hanging | 3.0 | 3.5 | 4.5 | ||||

| Weight | 61 kg | 82 kg | 110kg | ||||

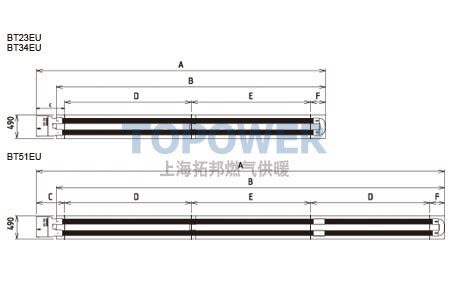

| Model | Amm | Bmm | Cmm | Dmm | Emm | Fmm | Gmm | Hmm |

|---|---|---|---|---|---|---|---|---|

| BT23EU | 4950 | 4550 | 545 | 2130 | 2030 | 245 | 490 | 262 |

| BT34EU | 5755 | 5353 | 565 | 2520 | 2370 | 300 | 490 | 290 |

| BT51EU | 8330 | 7980 | 565 | 2550 | 2370 | 300 | 490 | 320 |

most widely used in all types of buildings with large heated area